DS Smith International, Kemsley

Fig 1: Overall view of site from the South – F-Line location S/E bottom right corner

Client: DS Smith International

Project: F-Line Kemsley

Value: ~£50m

Evans & Langford have long been involved in the papermaking and packaging industry, we have gained a widely respected reputation in this sector and have worked with a number of European partners in design and management of such projects.

DS Smith is a paper manufacturing factory established in Kemsley from 1924, Kent has long been the papermaking heart of the UK and many such mills used to exist, sadly most have since disappeared. As primary suppliers for boxes and packaging to the Amazon shopping brand, demand for their product has soared in recent years. The collection and recycling of any general packaging and brown boxes for re-use is a key part of their investment benefits.

DS Smith provide a full recycling and waste management service, they are Europe’s largest cardboard and paper recycler and also one of the leading full service recycling and waste management companies in Europe. DS Smith collect quality paper and cardboard for recycling from a range of sectors, which produces cost efficient and sustainable raw materials for the Group’s recycled paper making processes.

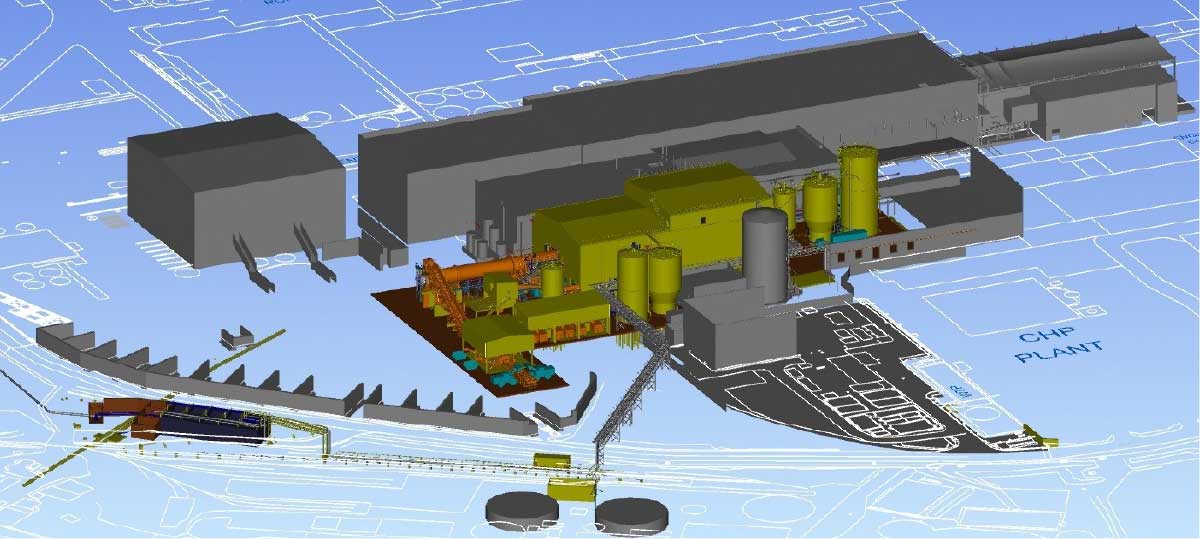

Evans & Langford have undertaken many projects at Kemsley, we were involved in the C D & E lines as well as other projects including machine upgrades, new perimeter road, primary water supply also waste recycling and energy saving around the site. The £50M F-Line project is to build the next line which will incorporate a new water recovery system, state of the art drum pulping and screening process, to eliminate contaminants. Apart from diminishing the production risks from failure of the existing lines, there are significant financial savings obtained through cost reductions.

Fig 2: N/E view towards building site constrained on all sides as part of yard is operational

This F-line project has lead to complete local site refurbishment and modernisation, with much investment in new equipment and also state of the art plant, as well as the upgrading of all Kemsley Mill site. It is situated on the edge of a RAMSAR site of special scientific interest and works continued with seasonal demolition, without disturbance to local birdlife, flora and fauna or the river. The paper mill has a biodiversity programme in place together with a comprehensive water management plan, achieving 10% reduction in water withdrawal per tonne of production at the mill, mitigating the risk of water stress.

The new facility was situated on a redundant part of the mill, so there was no shortage of obsolete foundations and drain culverts, these also needed to be extracted to allow for the installation of the new piles and drainage. All of the retrieved concrete excavated was crushed on site, recycled to generate over 10,000T of capping fill material which was used for backfilling soft spots, voids and excavations. As a result, no concrete was exported to landfill and no fill was imported and so omitting over 1,000 lorry journeys on the highway and saving over £100,000 by not needing to import the material from a quarry. This has contributed to a 50% reduction in waste to landfill in recent years and the site is on track to achieve zero waste to landfill by 2030.

Fig 3: Looking North at site location between existing buildings, pipebridge & storage tanks

The building was located on a revitalised part of the Mill, that is surrounded by operating lines and bale storage, whilst this made the logistics a lot more challenging, it meant there was no impact on the site or the surrounding area which is highlighted by aerial drone shots attached. The construction was phased to enable half the bale storage yard and perimeter wall construction ahead of the remainder, to create some new storage and working space.

Adjacent production lines and the south perimeter road remained in full operation throughout the construction programme, the delivery and installation of a 40m long pulper drum was the major logistics challenge. Initially this was intended to arrive in three parts and be welded up on site, but constraints and excessive costs eventually lead to the whole length being manufactured in China and delivered by specialist trailer.

Fig 4: Close up view of pulper drum and compactor building looking towards main block A

This project represents a major investment in the future of Kemsley Mill, having a total value of about £50 million. With the main structures now in place, most of the new plant and all of the machinery has been installed, with the next phase also focussing on the installation of the electrical suite and MCC equipment, that will control the whole fibre preparation journey. This includes fitting new process equipment and much electrical cabling, sufficient to stretch an impressive 77Km end-to-end, also extensive stainless steel piping to integrate all plant and machinery process systems.

Fig 5: Overview 3D model of new F-line buildings in yellow within existing grey structures

The project is a fitting regeneration project carried out since the original start of site operations and concluding at the end of 2025 around 100 years later, as DS Smith become part of the International Paper Group. Hence it has been a remarkable project where an S&P 500 International company has achieved its CAPEX goal by employing the local Kent supply chain.